CAE Simulation | Siemens Digital Industries Software

|

|

CAE 仿真Engineer innovation through the prediction of product performance 当您在创造新的改进产品时,您的设计将通过大量增量更改而不断演进。您需要能够对这些预期改进会如何影响实际性能进行预测,无论此影响是好是坏。 计算机辅助工程仿真使工程师能够预见未来,以预测任何设计更改对他们产品实际性能的影响。有效部署后,它可以用于通过多次迭代来改进设计,可可提供相应数据以指导从设计最初阶段直到生产及其他阶段的整个过程。 此产品包含出色的仿真工具,可提供所有工业计算机辅助工程 (CAE) 工具的全套物理模型。通过采用一种毫无折衷的物理建模方法,您可确信在产品的整个操作范围上,您的预测与实际产品行为皆可相符。 |

|

|

|

|

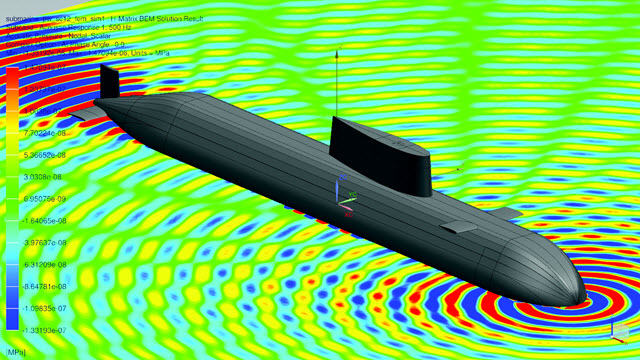

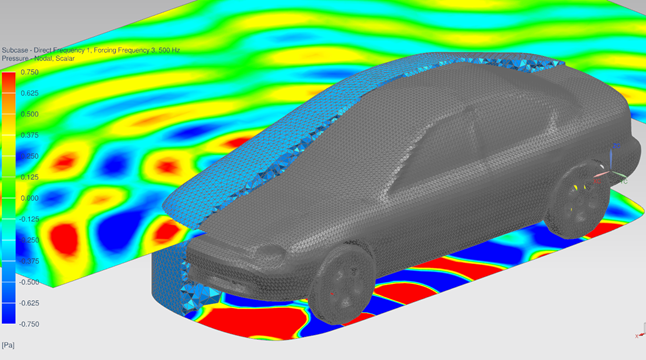

Acoustics simulation声学分析 Simcenter 在集成式环境中提供内场和外场声学分析,帮助您在早期设计阶段做出明智决策,从而能够优化产品的声学性能。可扩展的一体化建模环境与高效的解算器和易于解读的可视化功能完美结合在一起,让您能够快速获得对产品声学性能的洞察。 |

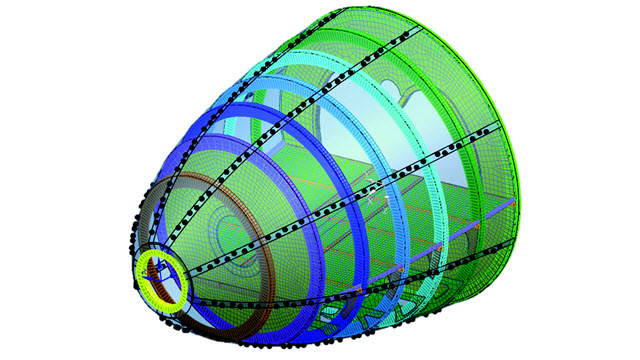

Aerostructures Simulation Simcenter can help you meet shorter timelines and reduce structural analysis costs with the ability to perform end-to-end aerostructure assessment in a fully integrated environment. |

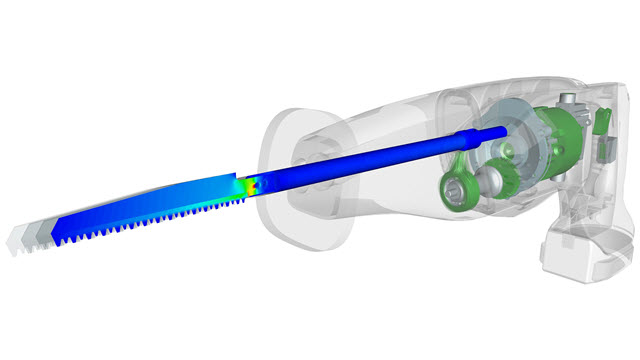

Dynamics Simulation Simcenter offers a comprehensive solution to understand, analyze and improve the response when a system is subjected to dynamic loading. |

|

|

|

|

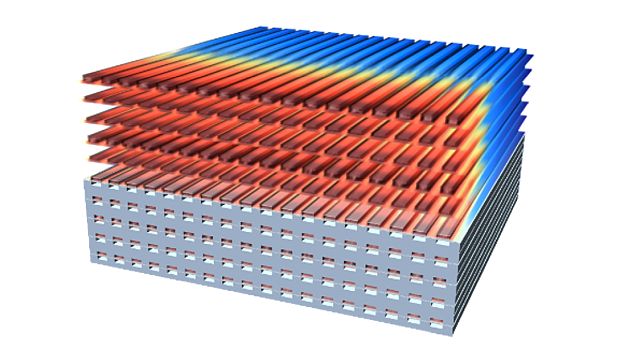

Electrochemistry Simulation Significantly improving a battery design across its whole operating range is a challenging task, and involves the simultaneous optimization of numerous parameters. Simcenter provides a complete simulation environment for the analysis and design of the electrochemical system and detailed geometry of individual battery cells. |

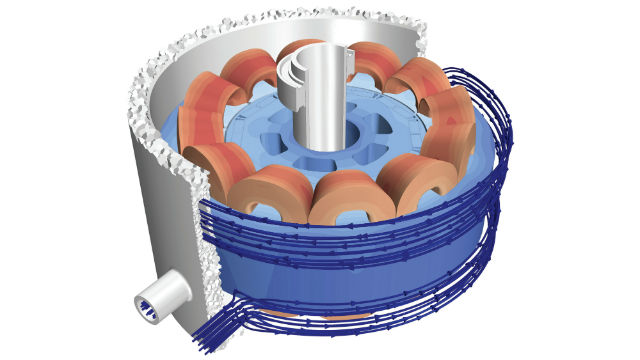

Electromagnetic Simulations Simcenter includes distinct low and high-frequency electromagnetic simulation capabilities for the unique demands in each domain. Expand your insight into the performance of electromechanical components, energy conversion, the design and siting of antennas, electromagnetic compatibility (EMC) and electromagnetic interference (EMI). |

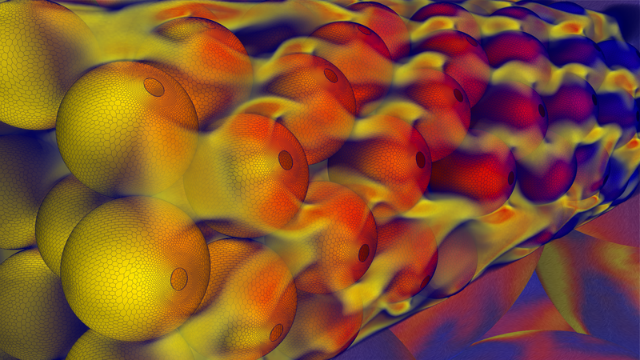

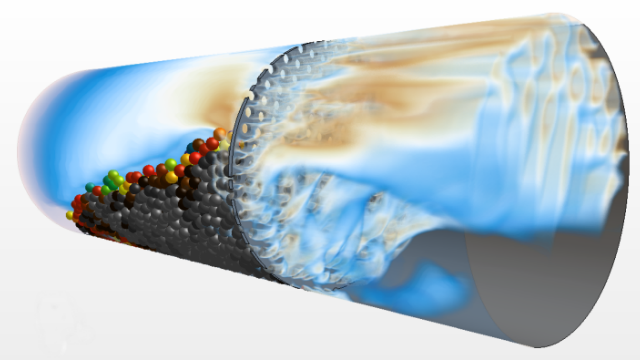

Fluid dynamics simulation流体动力学仿真 Simcenter 提供了业界前沿的计算流体动力学软件,让您得以对任何包含液体流或气体流(或两者的组合)和所有关联物理场的工程问题进行模拟。 |

|

|

|

|

Materials Engineering材料工程 使用一个数字化流程验证质量。 该闭环解决方案将 CMM 检测编程、执行和测量数据分析无缝地衔接在一起,以满足对产品质量的严苛要求。 |

Motion simulation运动分析 了解错综机械系统(例如复印机、滑动天窗或襟翼)的运作环境是一件棘手的事情。运动仿真将计算机械系统的反作用力、扭矩、速度、加速度等。您可以直接将 CAD 几何体和装配限制转换到准确的运动模型当中,也可以从头开始创建您自己的运动模型。通过嵌入式运动解算器和强大的后处理功能,对大量产品行为进行研究。 |

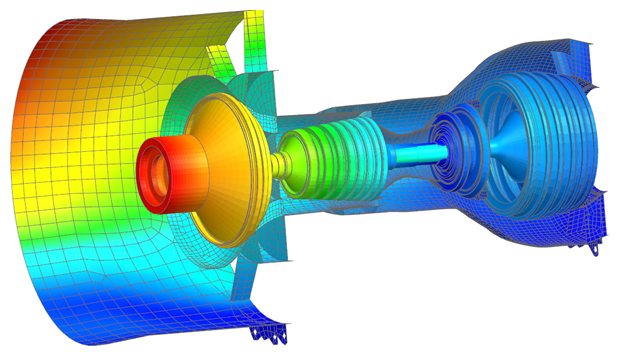

Multiphysics Simulation多学科仿真 Complex industrial problems require solutions that span a multitude of physical phenomena, which often can only be solved using simulation techniques that cross several engineering disciplines. |

|

|

|

|

Occupant Safety Simulation乘员安全仿真 通过使用集成了多种方法的解决方案和经过验证的碰撞假人和人体模型数据库,准确而高效地模拟乘客和行人的安全性。 |

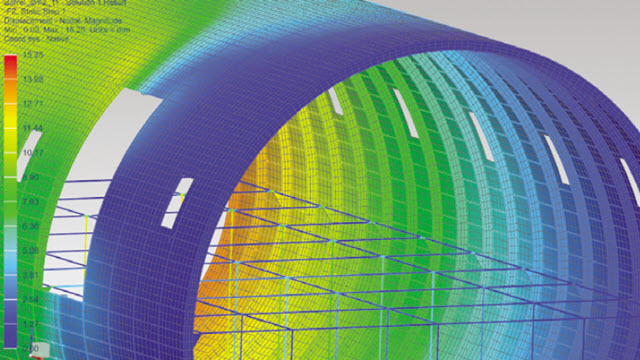

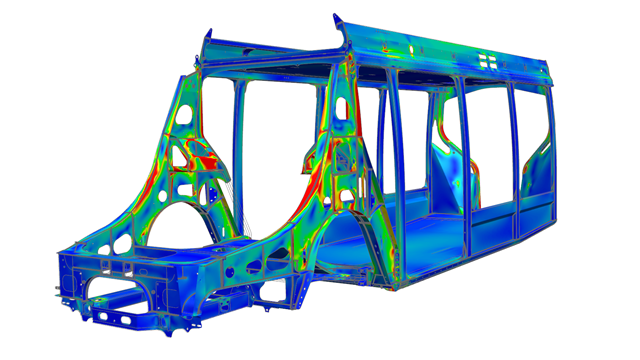

Structural simulation结构分析 不论所处行业为何,了解组件或产品装配体在应力或振动条件下如何反应都至关重要;面对越来越复杂的产品和材料,除了线性静力学分析,工程师还需要其他工具。Simcenter 将解决广泛的结构分析问题所需的解决方案集成到一个单一的用户环境中。 |

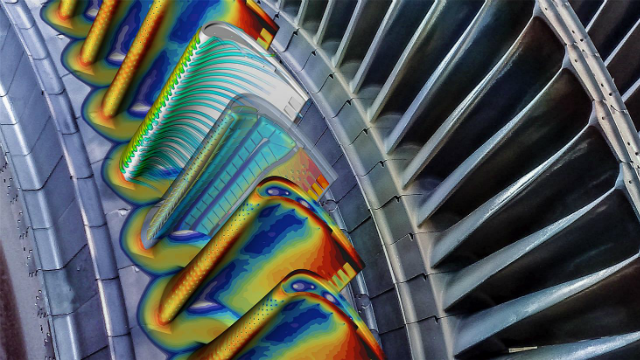

Thermal simulation热分析 Simcenter 包含了综合齐全的出色热仿真功能,可帮助您了解产品的热特征,继而调整您的热管理解决方案以优化性能。 |

|

|

|

|

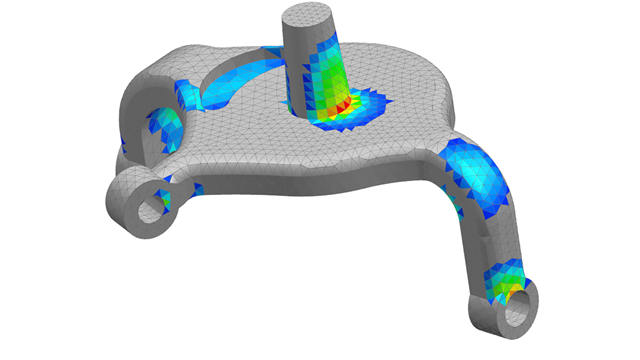

耐久性仿真 Simcenter 能够通过最先进的分析方法快速、准确地进行疲劳寿命预测分析,同时兼顾真实载荷情况。 |

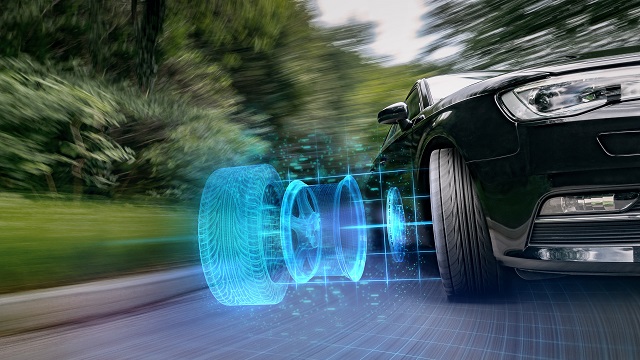

轮胎仿真与测试 借助可扩展、可定制的轮胎建模帮助,从轮胎模型到参数估算工具,再到工程和测试服务。 |

Meshing Efficiently mesh your models using extensive modeling functions for automatic and manual mesh generation of 1D, 2D and 3D elements in addition to numerous techniques for the application of loads and boundary conditions. User-defined geometry edits, mesh and boundary conditions are all associated to the base design, which means when the base design geometry changes, you can rapidly update your model. This approach greatly reduces downstream modeling time, which results in huge time savings across a project’s many design-analysis iterations. |

|

|

|

|

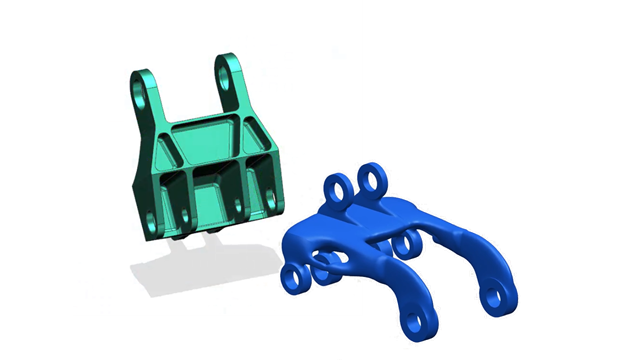

Optimization How can I reduce material in a component or change its properties while ensuring it continues to meet performance targets? Simcenter delivers engineering optimization techniques that can help you answer these this question by systematically searching for the best design that satisfies certain criteria. Reduce component weight or find the right combination of parameters to improve product performance through comprehensive topology, geometry, and parameter optimization capabilities. |

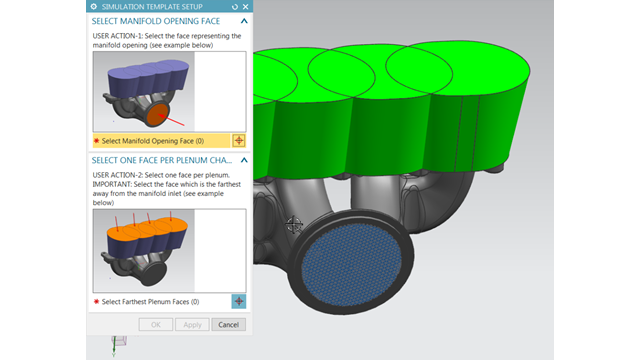

Simulation-driven Design Frontload simulation in your design cycle and shift your development processes further left. You can now embed simulation directly into your design environment and processes to truly enable simulation-driven design. |

Pre / Postprocessing 减少分析模型的准备时间,从而有更多时间用于结果评估。使用专门针对 CAE 几何体编辑、综合网格划分、有限元装配管理、多 CAE 解算器环境和快速仿真结果后处理和报告的工具,迅速从多 CAD 几何体数据转变为完整、可用的分析模型 |

|

|

|

|

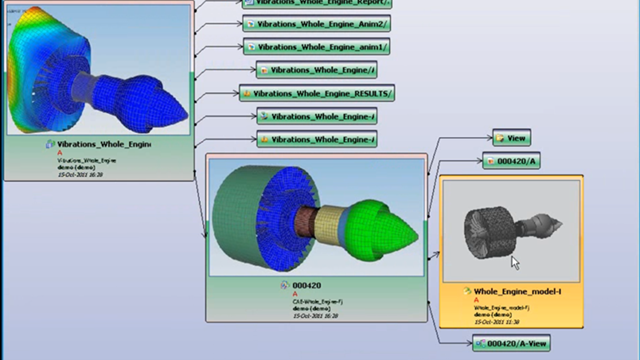

Simulation Automation & Scalability As companies increase their reliance on simulation, they are seeking ways to speed-up the analysis process and increase simulation throughput. One way to increase simulation throughput is to capture repetitive CAE processes, standardize them, and then automate them. Simcenter allows you to capture the expertise of senior analysts and make it available for junior engineers in your organization to use in the form of wizards or templates. |

Simulation Data Management The pressure to shorten time-to-market while improving product performance and quality is driving the increased use of simulation throughout the product lifecycle. However, without some form of simulation data management, simulation itself can become a process bottleneck. Simulation data management helps you get control of your simulation data and processes to avoid common problems such as analyses being performed on obsolete data. You can efficiently manage and share complex product simulations so they are available to all product decision-makers across your business. |